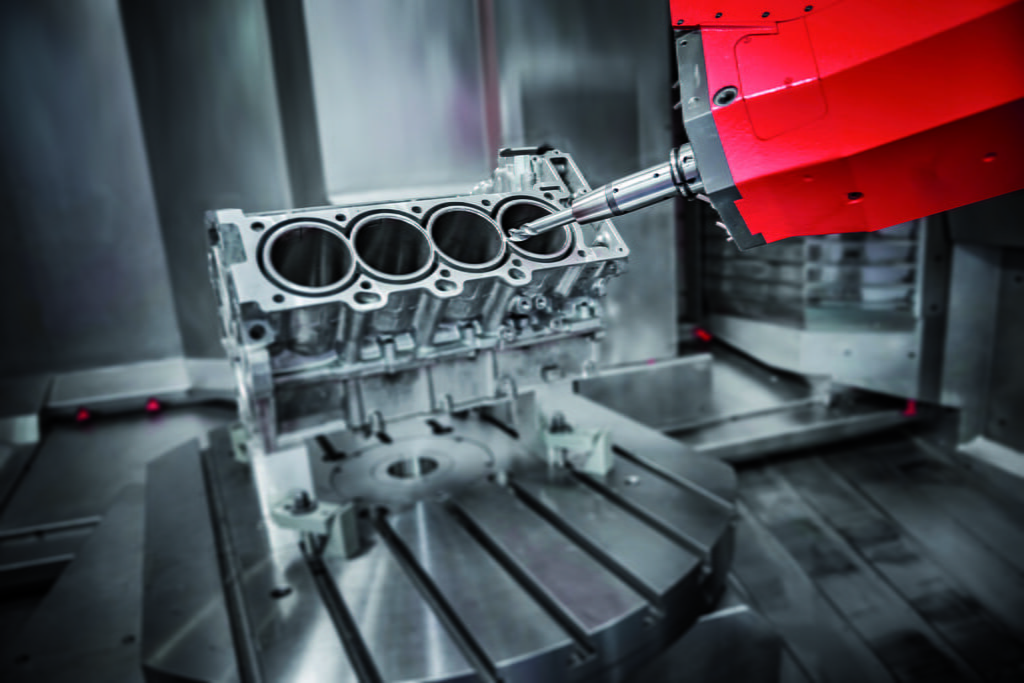

When you’re prepping an engine block—whether for a high-performance build or a standard refresh—the right engine block machining services are critical. From basic cleaning to precision machining, each step plays a role in the performance and longevity of your engine. Here’s a detailed guide on the essential engine block machining services you’ll need, along with cost estimates for 2024.

Engine Machine Work

Cylinder Boring:

- Purpose: If you’ve got worn-out cylinders or oversized pistons, boring makes sure everything fits perfectly and keeps the block healthy.

- Process: This involves removing material from the cylinder walls for a round, straight bore.

- Cost: $15 – $60 per cylinder.

Cylinder Honing:

- Purpose: After boring, honing creates the proper crosshatch pattern on the cylinder walls for oil retention and ring seating.

- Cost: $10 – $20 per cylinder (or $60 – $120 for a full set).

Decking:

- Purpose: Ensures the block’s deck is flat and ready for a proper seal with the heads, preventing future head gasket problems.

- Cost: $125 – $285.

Align Boring/Honing:

- Purpose: Keeping the main bearing bores aligned is crucial for longevity and smooth operation. Misalignment leads to early wear.

- Cost: $75 – $150 for align honing, with more extensive align boring running up to $410.

Balancing:

- Purpose: A balanced rotating assembly (crankshaft, rods, pistons) means reduced vibration, improved power output, and longer engine life.

- Cost: $300 – $400 for a full assembly.

Crankshaft Grinding/Polishing:

- Purpose: If your crankshaft has worn journals, grinding and polishing can restore them to a smooth, round surface, ensuring good bearing contact.

- Cost: $85 – $200.

Sleeving:

- Purpose: If your cylinder walls are damaged or worn beyond standard repair, sleeving replaces the material with new sleeves.

- Cost: $75 – $150 per cylinder.

O-Ringing:

- Purpose: To improve head gasket sealing, especially in high-performance applications, O-ringing adds a sealing wire groove around the bores.

- Cost: $150 – $315.

Cleaning and Prep Work

Hot Tanking:

- Purpose: A hot tank chemical bath strips old oil, sludge, and contaminants from your block.

- Cost: $60 – $150.

Vapor Blasting:

- Purpose: For a clean surface without removing material, vapor blasting uses a high-pressure water and abrasive mix.

- Cost: $100 – $200.

Ultrasonic Cleaning:

- Purpose: Ultrasonic waves clean even the smallest crevices, ensuring all dirt and contaminants are removed.

- Cost: $75 – $150.

Magnafluxing:

- Purpose: Looking for cracks or defects? Magnafluxing uses a magnetic field and powder to find problems invisible to the naked eye.

- Cost: $20 – $100 depending on the part (heads, blocks, etc.).

Pressure Testing:

- Purpose: Before putting a block into service, pressure testing ensures it can handle the load without leaks.

- Cost: $30 – $100.

Surface Grinding:

- Purpose: Machining the mating surfaces flat ensures proper seals, reducing the risk of leaks or uneven wear.

- Cost: $100 – $200.

Freeze Plug Replacement:

- Purpose: Replacing freeze plugs prevents future leaks and protects your cooling system from corrosion.

- Cost: $30 – $60.

Thread Repair:

- Purpose: If threads in the block are damaged, thread inserts like helicoils can restore them.

- Cost: $50 – $100 per thread.

High-Performance Prep

Clearancing:

- Purpose: Running a stroker crank or oversized cam? Clearancing makes sure there’s enough room for everything to move freely.

- Cost: $100 – $200.

Main Cap Girdling:

- Purpose: For high-performance builds pushing serious power, adding a girdle strengthens the main caps, preventing movement and distortion.

- Cost: $200 – $400.

Refreshing an Engine (Non-Performance Build)

If you’re doing a standard refresh to bring an older engine back to solid working condition, the services you’ll need focus more on cleaning, inspection, and minor restoration rather than performance modifications. Here are the key services you’d likely need:

- Hot Tanking: To clean out all the sludge and grime.

- Cylinder Honing: If the cylinder walls are in decent shape, honing can restore the surface for good ring seating.

- Decking: To ensure a flat surface for the heads and prevent head gasket issues.

- Magnafluxing: This checks for cracks or hidden defects in the block.

- Freeze Plug Replacement: Older blocks often need new freeze plugs to prevent leaks.

- Thread Repair: If any of the block’s threads are damaged, repairing them ensures a secure fit for fasteners.

Estimated Cost for a Refresh:

For a standard rebuild, expect to spend $500 – $900 on these core engine block machining services.

High-Performance Build

When building a performance engine, the list of engine block machining services expands to ensure the block can handle increased power and stress. Essential services include:

- Hot Tanking: Essential to clean all old grime, oil, and sludge from the block.

- Magnafluxing: Checks for cracks and structural integrity, critical in high-performance builds where added stress can exacerbate small defects.

- Freeze Plug Replacement: Old freeze plugs could leak under high pressure or heat, so replacing them ensures the cooling system is leak-free.

- Thread Repair: Damaged threads need fixing to handle the extra torque on fasteners.

- Cylinder Boring: For oversized pistons and increased displacement.

- Cylinder Honing: After boring, honing ensures proper piston ring seating and oil retention.

- Decking: Guarantees a flat deck surface for optimal head gasket sealing under high compression.

- Align Boring/Honing: Keeps the main bearing bores aligned for smooth operation at high RPMs.

- Balancing: Balances the crank, rods, and pistons to reduce vibrations and prolong engine life.

- Crankshaft Grinding/Polishing: Smooths out crank journals for better bearing contact.

- Main Cap Girdling: Adds strength to handle increased stress and power.

- O-Ringing: Improves head gasket sealing for high-compression or forced-induction setups.

- Clearancing: Ensures there’s enough room for larger components like a stroker crank or oversized camshaft.

- Oil Passage Modifications: Improves oil flow for better lubrication under high load and RPMs.

Estimated Cost for a Performance Build:

Including all the necessary cleaning, testing, and advanced machining, you’re looking at $1,500 – $4,000, depending on the shop and the specific needs of your build. Not all builds will need all these services. Check with your shop to see what they recommend for your specific situation.

Final Thoughts:

When building or upgrading an engine for performance, choosing the right services from your machine shop can make or break your project. While the costs can vary by region and shop, this guide should give you a solid idea of what to expect. Don’t forget to ask about package deals, as many shops will bundle services to save you some cash.

Building a performance engine is a big investment, but with the right prep work and machining, you’ll be rewarded with an engine that delivers both power and reliability for years to come.

If you want more specific information on Bullnose Ford Trucks, check out my YouTube Channel!

For more information on Bullnose Fords, you can check out the BullnoseFord SubReddit or Gary’s Garagemahal. Both are excellent resources.